The cam-type double rotor pump is a high-tech and top-notch fluid delivery equipment imported and developed by LAFA from Sweden, and it is a multi-functional new rotor pump manufactured with advanced technology. The professional manufacturing technology and manufacturing precision of the products fully meet the international level.

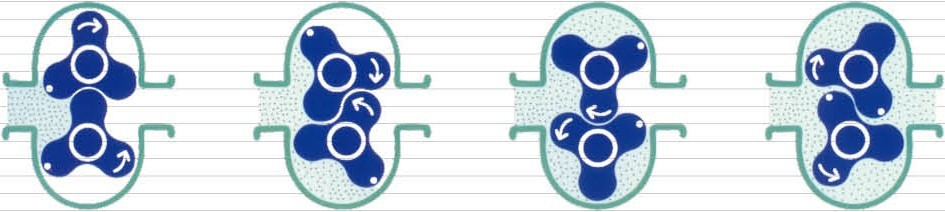

This product uses two synchronous rotors, the rotors are driven by a pair of synchronous gears in the box, and the rotors are driven by the main and auxiliary shafts to rotate synchronously in the opposite direction to make the pump The inner cavity of the pump is changed, thus forming a higher vacuum degree and discharge pressure, which is more suitable for the transportation of sanitary grades and corrosive high-viscosity media.

The manufacturing standards of this product are divided into five series: food grade, common type, special type, chemical type, and oil type. In terms of structure, it can be divided into two categories: high pressure and high viscosity, high pressure and low viscosity.

With the superior performance of the cam-type double-rotor pump, it can replace more commonly used centrifugal pumps, single-screw pumps, twin-screw pumps, etc.

Type | Capacity (L/r) | Flow (m3/h) | Power (kw) | Rotation speed (r/min) | Inlet&outlet (mm) |

15LF12-0.6A | 0.04 | 0.6 | 0.25-1.5 | 10-720 | 10 |

25LF12-2A | 0.15 | 2 | 0.25-2.2 | 10-721 | 25 |

40LF12-5A | 0.32 | 5 | 0.37-3.0 | 10-500 | 40 |

50LF12-10A | 0.65 | 10 | 1.5-7.5 | 10-500 | 50 |

60LF12-15A | 1.1 | 15 | 2.2-11 | 10-500 | 65 |

65LF12-20A | 1.74 | 20 | 2.2-15 | 10-500 | 65 |

75LF12-30A | 2.6 | 30 | 3.0-22 | 10-500 | 80 |

80LF12-40A | 3.65 | 40 | 4.0-30 | 10-500 | 80 |

100LF12-60A | 5.2 | 60 | 5.5-45 | 10-500 | 100 |

125LF12-80A | 6.8 | 80 | 7.5-55 | 10-500 | 125 |

140LF12-120A | 9.8 | 120 | 11-90 | 10-400 | 150 |

150LF12-150A | 12.8 | 150 | 15-160 | 10-400 | 150 |

200LF12-200A | 16 | 200 | 18.5-185 | 10-300 | 200 |

300LF12-300A | 24 | 300 | 22-185 | 10-270 | 300 |

校正

高粘度泵和电机的不对时会使轴向轴承负载。当测算不对里时,轴向轴承寿命是一个指数因素。比如,针对只有1.52mm的小误差,终端用户在运作三到五个月后可能会遇到某种轴承或连轴器难题。可是,针对0.0254mm的误差,同一台泵可能会运作90个月以上。

管道应力

管道应力是由于吸入管或排出管与泵法兰的不对中引起的。比如有的客户会反馈进出口法兰处在使用中有裂缝,可是泵出厂时是实验合格的,则不清除管道施工时会管道应力。即便在坚固的泵设计里,产生的管道应力也可以很容易地把这些隐性的高作用力传达给轴承以及各自的外壳。力(应变)造成树脂输送泵轴承配合不当和/或与其它轴承不一致,从而使轴线位于不同的平面上。

液体特性

液体特性如pH值、黏度和比例是关键因素。假如物质是酸性或腐蚀性的,泵的触碰部分,如外壳和叶轮材料,必须维持作用情况。液体中出现的固态数量以及尺寸、形状和研磨品质都将是影响因素。