The cam-type double rotor pump is a high-tech and top-notch fluid delivery equipment imported and developed by LAFA from Sweden, and it is a multi-functional new rotor pump manufactured with advanced technology. The professional manufacturing technology and manufacturing precision of the products fully meet the international level.

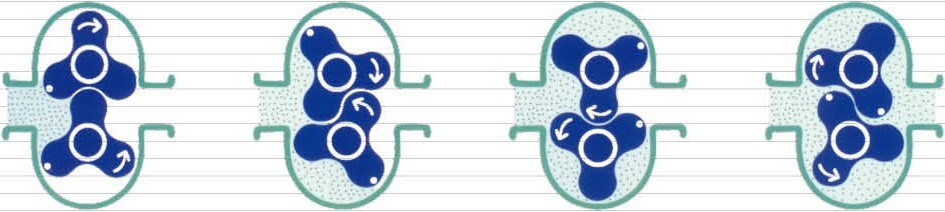

This product uses two synchronous rotors, the rotors are driven by a pair of synchronous gears in the box, and the rotors are driven by the main and auxiliary shafts to rotate synchronously in the opposite direction to make the pump The inner cavity of the pump is changed, thus forming a higher vacuum degree and discharge pressure, which is more suitable for the transportation of sanitary grades and corrosive high-viscosity media.

The manufacturing standards of this product are divided into five series: food grade, common type, special type, chemical type, and oil type. In terms of structure, it can be divided into two categories: high pressure and high viscosity, high pressure and low viscosity.

With the superior performance of the cam-type double-rotor pump, it can replace more commonly used centrifugal pumps, single-screw pumps, twin-screw pumps, etc.

Type | Capacity (L/r) | Flow (m3/h) | Power (kw) | Rotation speed (r/min) | Inlet&outlet (mm) |

15LF12-0.6A | 0.04 | 0.6 | 0.25-1.5 | 10-720 | 10 |

25LF12-2A | 0.15 | 2 | 0.25-2.2 | 10-721 | 25 |

40LF12-5A | 0.32 | 5 | 0.37-3.0 | 10-500 | 40 |

50LF12-10A | 0.65 | 10 | 1.5-7.5 | 10-500 | 50 |

60LF12-15A | 1.1 | 15 | 2.2-11 | 10-500 | 65 |

65LF12-20A | 1.74 | 20 | 2.2-15 | 10-500 | 65 |

75LF12-30A | 2.6 | 30 | 3.0-22 | 10-500 | 80 |

80LF12-40A | 3.65 | 40 | 4.0-30 | 10-500 | 80 |

100LF12-60A | 5.2 | 60 | 5.5-45 | 10-500 | 100 |

125LF12-80A | 6.8 | 80 | 7.5-55 | 10-500 | 125 |

140LF12-120A | 9.8 | 120 | 11-90 | 10-400 | 150 |

150LF12-150A | 12.8 | 150 | 15-160 | 10-400 | 150 |

200LF12-200A | 16 | 200 | 18.5-185 | 10-300 | 200 |

300LF12-300A | 24 | 300 | 22-185 | 10-270 | 300 |

运行状态

运行状态的严格水平是另一个主要因素:在给出时间内化工助剂泵多久启动一次?有些泵每过几秒就启动和终止一次。与在相同条件下连续运行的泵相比,这些工作上的泵以指数级速度损坏。在这种情况下,系统设计急需改变。

汽蚀余量

可用净正吸进拉力(NPSHA)的裕度越大,超出所需净正吸进拉力(NPSHR),泵发生气蚀的概率就越低。空蚀会毁坏泵叶轮,而且产生的震动会影响密封件和轴承。

泵转速

泵的运行速度是另一个关键因素。比如同一台三螺杆泵,2900转/分钟的泵则会比960转/分钟的泵要损坏的快。

转子均衡

不论是离心泵、容积泵(齿轮泵、转子泵)等,关键转子的平衡状态很重要,不平衡,则直接关系泵的寿命。

管道施工

宁波转子泵的选型应当融合管道的设计,管路进口一定要符合泵的自吸能力,管路出口的阻力则要满足泵的设计压力,不然会影响自吸及下料。