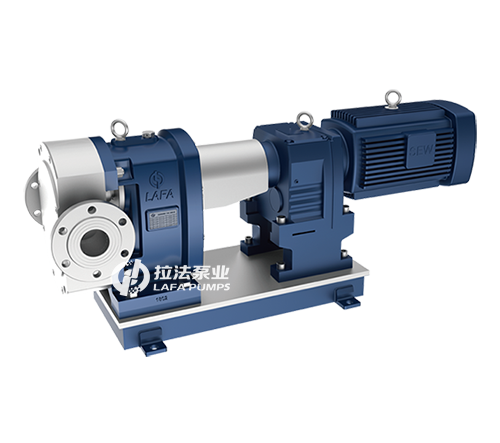

The cam-type double rotor pump is a high-tech and top-notch fluid delivery equipment imported and developed by LAFA from Sweden, and it is a multi-functional new rotor pump manufactured with advanced technology. The professional manufacturing technology and manufacturing precision of the products fully meet the international level.

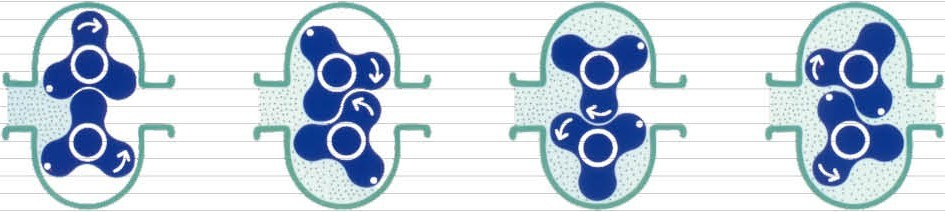

This product uses two synchronous rotors, the rotors are driven by a pair of synchronous gears in the box, and the rotors are driven by the main and auxiliary shafts to rotate synchronously in the opposite direction to make the pump The inner cavity of the pump is changed, thus forming a higher vacuum degree and discharge pressure, which is more suitable for the transportation of sanitary grades and corrosive high-viscosity media.

The manufacturing standards of this product are divided into five series: food grade, common type, special type, chemical type, and oil type. In terms of structure, it can be divided into two categories: high pressure and high viscosity, high pressure and low viscosity.

With the superior performance of the cam-type double-rotor pump, it can replace more commonly used centrifugal pumps, single-screw pumps, twin-screw pumps, etc.

Type | Capacity (L/r) | Flow (m3/h) | Power (kw) | Rotation speed (r/min) | Inlet&outlet (mm) |

15LF12-0.6A | 0.04 | 0.6 | 0.25-1.5 | 10-720 | 10 |

25LF12-2A | 0.15 | 2 | 0.25-2.2 | 10-721 | 25 |

40LF12-5A | 0.32 | 5 | 0.37-3.0 | 10-500 | 40 |

50LF12-10A | 0.65 | 10 | 1.5-7.5 | 10-500 | 50 |

60LF12-15A | 1.1 | 15 | 2.2-11 | 10-500 | 65 |

65LF12-20A | 1.74 | 20 | 2.2-15 | 10-500 | 65 |

75LF12-30A | 2.6 | 30 | 3.0-22 | 10-500 | 80 |

80LF12-40A | 3.65 | 40 | 4.0-30 | 10-500 | 80 |

100LF12-60A | 5.2 | 60 | 5.5-45 | 10-500 | 100 |

125LF12-80A | 6.8 | 80 | 7.5-55 | 10-500 | 125 |

140LF12-120A | 9.8 | 120 | 11-90 | 10-400 | 150 |

150LF12-150A | 12.8 | 150 | 15-160 | 10-400 | 150 |

200LF12-200A | 16 | 200 | 18.5-185 | 10-300 | 200 |

300LF12-300A | 24 | 300 | 22-185 | 10-270 | 300 |

1、径向力

保温型转子泵厂家行业统计数据说明,离心泵终止运转的较大原因是轴承和/或机械密封件的故障。不止是离心泵,容积泵的寿命也是受径向力的影响。径向力大和随着产生的轴挠度是机封的凶手,是减少轴承寿命的关键因素。假如足够大,则径向力会导致轴偏移或弯折。假如终止泵并测量轴上的跳动,则不会出现任何错误,因为它是动态标准,而非静态标准。

2、润滑脂的污染

针对球轴承,超出85%的轴承故障是由于污物、异物或水进到而导致的。合理使用洁净的润滑脂对寿命尤为重要。

3、吸入压力

影响轴承寿命的许多关键因素也有吸入压力、连轴器对准及其管道应力。在凸轮式双转子泵定制选型时,吸入压力是很重要的参照参数之一,假如吸入压力太高或存在真空,则要考虑是不是在泵的自吸范围内,还要考虑泵进口机封的承压。