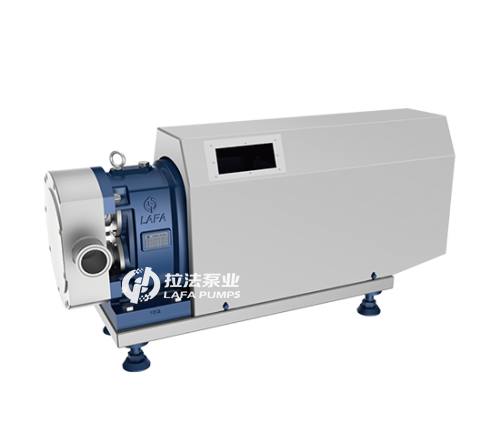

The cam-type double rotor pump is a high-tech and top-notch fluid delivery equipment imported and developed by LAFA from Sweden, and it is a multi-functional new rotor pump manufactured with advanced technology. The professional manufacturing technology and manufacturing precision of the products fully meet the international level.

This product uses two synchronous rotors, the rotors are driven by a pair of synchronous gears in the box, and the rotors are driven by the main and auxiliary shafts to rotate synchronously in the opposite direction to make the pump The inner cavity of the pump is changed, thus forming a higher vacuum degree and discharge pressure, which is more suitable for the transportation of sanitary grades and corrosive high-viscosity media.

The manufacturing standards of this product are divided into five series: food grade, common type, special type, chemical type, and oil type. In terms of structure, it can be divided into two categories: high pressure and high viscosity, high pressure and low viscosity.

With the superior performance of the cam-type double-rotor pump, it can replace more commonly used centrifugal pumps, single-screw pumps, twin-screw pumps, etc.

Type | Capacity (L/r) | Flow (m3/h) | Power (kw) | Rotation speed (r/min) | Inlet&outlet (mm) |

15LF12-0.6A | 0.04 | 0.6 | 0.25-1.5 | 10-720 | 10 |

25LF12-2A | 0.15 | 2 | 0.25-2.2 | 10-721 | 25 |

40LF12-5A | 0.32 | 5 | 0.37-3.0 | 10-500 | 40 |

50LF12-10A | 0.65 | 10 | 1.5-7.5 | 10-500 | 50 |

60LF12-15A | 1.1 | 15 | 2.2-11 | 10-500 | 65 |

65LF12-20A | 1.74 | 20 | 2.2-15 | 10-500 | 65 |

75LF12-30A | 2.6 | 30 | 3.0-22 | 10-500 | 80 |

80LF12-40A | 3.65 | 40 | 4.0-30 | 10-500 | 80 |

100LF12-60A | 5.2 | 60 | 5.5-45 | 10-500 | 100 |

125LF12-80A | 6.8 | 80 | 7.5-55 | 10-500 | 125 |

140LF12-120A | 9.8 | 120 | 11-90 | 10-400 | 150 |

150LF12-150A | 12.8 | 150 | 15-160 | 10-400 | 150 |

200LF12-200A | 16 | 200 | 18.5-185 | 10-300 | 200 |

300LF12-300A | 24 | 300 | 22-185 | 10-270 | 300 |

宁波转子泵在运行中常常产生卡住、抱轴固定状况,主要因素是高粘度转子泵、不锈钢板的高粘度转子泵常运输高粘度介质,有一些是一些残渣渗入物理中.假若泵的通道并没拼装适度的过滤装置,那麽高粘度耐热凸轮泵一旦很大的硬细颗粒物进到泵腔内,就会造成高粘度的泵电机卡住内外,使泵转无缘无故,较为严重会毁坏环境卫生级耐热凸轮泵电机内外的高粘度转子泵.

在凸轮式双转子泵选型环节中,经常遇到出口管道长度、管道直径已知,而客户自身不清楚压力状况,因此,科学计算管路损失十分必要。

欲使转子泵可靠工作需要限速。那么影响转速挑选的因素有哪些呢?

介质磨损性。介质磨损性直接影响到混和均质泵或是衬板的损坏程度,即影响到泵的使用期。介质特性越极端,黏胶浆粥泵转子与泵壳或是衬板必定越容易损坏,且泵转速越大,损坏就愈大。

介质为乳胶情况液态时,选择转速取决于其对转速的敏感程度,如从污油中分离油时,规定避免介质乳化加重,必要规定泵低速运作,一般转速不超过200r/min。