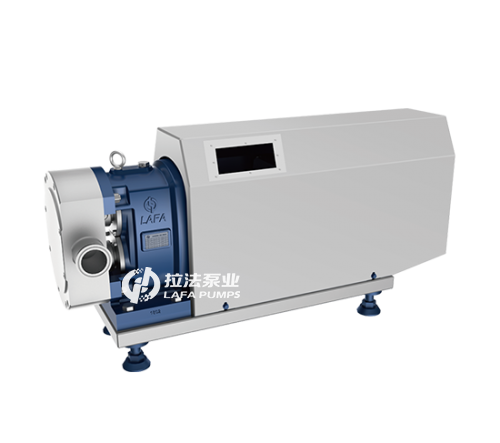

The cam-type double rotor pump is a high-tech and top-notch fluid delivery equipment imported and developed by LAFA from Sweden, and it is a multi-functional new rotor pump manufactured with advanced technology. The professional manufacturing technology and manufacturing precision of the products fully meet the international level.

This product uses two synchronous rotors, the rotors are driven by a pair of synchronous gears in the box, and the rotors are driven by the main and auxiliary shafts to rotate synchronously in the opposite direction to make the pump The inner cavity of the pump is changed, thus forming a higher vacuum degree and discharge pressure, which is more suitable for the transportation of sanitary grades and corrosive high-viscosity media.

The manufacturing standards of this product are divided into five series: food grade, common type, special type, chemical type, and oil type. In terms of structure, it can be divided into two categories: high pressure and high viscosity, high pressure and low viscosity.

With the superior performance of the cam-type double-rotor pump, it can replace more commonly used centrifugal pumps, single-screw pumps, twin-screw pumps, etc.

Type | Capacity (L/r) | Flow (m3/h) | Power (kw) | Rotation speed (r/min) | Inlet&outlet (mm) |

15LF12-0.6A | 0.04 | 0.6 | 0.25-1.5 | 10-720 | 10 |

25LF12-2A | 0.15 | 2 | 0.25-2.2 | 10-721 | 25 |

40LF12-5A | 0.32 | 5 | 0.37-3.0 | 10-500 | 40 |

50LF12-10A | 0.65 | 10 | 1.5-7.5 | 10-500 | 50 |

60LF12-15A | 1.1 | 15 | 2.2-11 | 10-500 | 65 |

65LF12-20A | 1.74 | 20 | 2.2-15 | 10-500 | 65 |

75LF12-30A | 2.6 | 30 | 3.0-22 | 10-500 | 80 |

80LF12-40A | 3.65 | 40 | 4.0-30 | 10-500 | 80 |

100LF12-60A | 5.2 | 60 | 5.5-45 | 10-500 | 100 |

125LF12-80A | 6.8 | 80 | 7.5-55 | 10-500 | 125 |

140LF12-120A | 9.8 | 120 | 11-90 | 10-400 | 150 |

150LF12-150A | 12.8 | 150 | 15-160 | 10-400 | 150 |

200LF12-200A | 16 | 200 | 18.5-185 | 10-300 | 200 |

300LF12-300A | 24 | 300 | 22-185 | 10-270 | 300 |

1、转子泵有较强的自吸能力,而离心泵在动转前必须先充满液体。

2、转子泵属容积式泵,输送流量能够较准确的控制,也可方便地制成变量泵。而离心泵的导出流量是不能控制的,随本身阻力的提高而降低。

3、转子泵能够方便地制成输出压力较高的种类,如15kg/cm2,适宜于远距离或高阻力定量输送。

4、转子泵的转速很低,一般在120rmp至600rmp之间,被输送的物料被平稳地导出并且成分不会受到损坏。而离心泵的转速很高,被输送物料遭受强悍的碰撞及其向心力的功效,因此离心泵在输送混合物时经常产生物质成分不一的状况,使成品的品质降低。而转子泵正是处理这一问题的好选择,因此它特别适用于输送混合料甚至含有固态颗粒的物料。

5、转子泵提升转子型线设计,脉冲稳定,偏差很小,震动很小,效率很高,这也是它和离心混合泵相比较大的区别。

6、转子泵适合于输送黏度很高的物质,因此又称胶体泵。而离心泵无此特点。