Flexible rotor pump is a kind of cam type double rotor pump, (HDRB) is widely used in many alternatives, strong self-priming, large flow, small size, low cost performance, known as energy saving Pump.

Product performance:

1. Strong self-priming, perfect structural principle, dry self-priming 6 meters, with material self-priming up to 9 meters.

2. Short self-priming time, self-priming within 6 meters within 2-3 seconds.

3. The structure is simple, the maintenance is convenient, no professional guidance is needed, and the maintenance does not need to dismantle the pump pipeline.

4. The pump is purchased once and used for a lifetime, with few wearing parts.

5. Small size and small space occupied by on-site equipment.

6 Massive flow and high efficiency, the smallest power and the most energy-saving under the same flow.

7. No noise for indoor installation.

8. It can transport hard particles containing particle impurities.

9. The viscosity of the conveying medium can reach 5000 centipoise.

Features:

Small size, large flow rate - Generally speaking, compared with competitive pumps, the volume is the smallest at the same flow rate. Easy to install and move.

Completely self-priming in an instant—no need for any additional devices, and no need for rehydration before starting. The suction lift can reach five meters.

The pump body is made of stainless steel precision casting, and all metal parts with flow are made of stainless steel (1Cr18Ni9Ti).

The viscosity of the conveying medium can reach 2000 centipoise.

It can transport air-containing liquid and foam liquid without air resistance.

It can transport medium containing suspended soft and hard particles.

The gentle action of the rotor does not damage media that are sensitive to shear, such as paper dispersions.

The flexible rotor has no metal contact and no sparks during operation; it is especially suitable for the transportation of alcohol, gasoline, acetone and other solvents after being equipped with an explosion-proof motor.

Beautiful appearance, durable and easy to maintain.

Apply:

The pump's excellent self-priming performance and strong adaptability to working conditions make it suitable for various industrial occasions, such as dumping barrels, sweeping warehouses, and storing liquid in underground pools. Suction and discharge, sampling and transportation of various fluids and semi-fluids. For example, when pouring a bucket, you only need to insert the inlet hose into the bucket to suck up the light. Widely replace centrifugal self-priming pumps, submerged pumps, gear pumps, single screw pumps and other pumps.

Chemical industry—weak inorganic acids, organic acids, alkalis, salts, oils, alcohols, ketones, esters and a wide range of media.

| Specification | Rated head (m) | Rated flow (m3/h) | Motor (KW) | speed (r/min) | Power (v) | Caliber |

| 15-HDRB | 30 | 1 | 0.37 (common/explosion-proof) | 1400 | 380/220V | 4 points |

| 20-HDRB | 30 | 2 | 0.55 (common/explosion-proof) | 1400 | 380/220V | 6 points |

| 25-HDRB | 30 | 5 | 0.75 (common/explosion-proof) | 1400 | 380/220V | 1 inch |

| 40-HDRB | 30 | 12 | 1.5(normal/explosion-proof) | 1400 | 380/220V | 1.5 inch |

| 50-HDRB | 30 | 18 | 3(normal/explosion-proof) | 1400 | 380V | 2 inches |

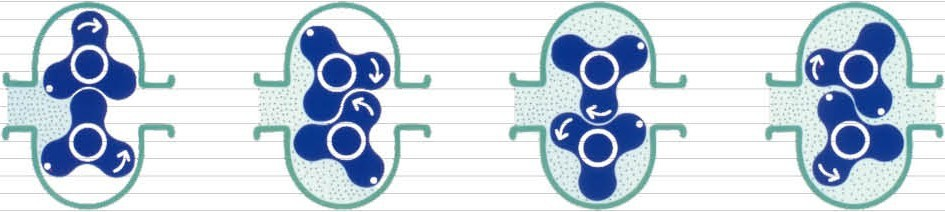

① There is an eccentric bump in the pump cavity. When the flexible blades leave the eccentric block, the volume between the blades increases continuously, creating a vacuum, which makes the liquid be sucked in continuously Inlet of the pump chamber.

② When the flexible vane rotates, the liquid is brought from the suction part of the pump chamber to the discharge part.

③ When the flexible blade touches the eccentric bump again, it bends, accompanied by a squeezing action, so that the liquid is discharged from the pump chamber without interruption and without pulsation. Thereby completing the whole process of suction and discharge.

AsThe core technology of flexible pump, the impeller of the pump should have good elasticity, small long-term deformation, and can Withstand long-term high-frequency flexing without breaking or tearing. "Ten years of grinding a sword", the excellent impeller elastomer technology determines the excellent performance and durability of the pump. There are two kinds of materials for the impeller——sanitary nitrile rubber and EPDM rubber; the nitrile impeller is mainly used for vegetable oil, mineral oil, oily medium and fields with high hygiene requirements; the ethylene propylene wheel is mainly used for weak inorganic acid , organic acids, alkalis, salts, alcohols, ketones, sewage and a wide range of media.

1、定期检查节能转子泵润滑脂品质,保持良好耳朵润化情况,以增加齿轮和轴承寿命。

2、每日查验泵的工作状态,出现异常响声和震动,或升温太高时要关机查验。

3、维修时要把进出口闸阀关掉,同时开启排清阀将泵腔内液体排清,以防拆装时泵体内带压液态致伤。

4、当泵壳震动和声响较大时,可能是联轴不对中或负荷太大造成,应查明原因。

5、电机因故障维护关机时,应断电查验。若操作正确,可分析判断是设备故障,开启泵盖若发现凸轮之间和凸轮与腔壁之间有划痕,首先要查其空隙。

6、当凸轮表层发生较深刮痕时,应选下凸轮及密封,将凸轮式双转子泵加工表面抛光并查验侧面的平整度,同事将泵腔内壁的划痕处理光滑。

7、在泵拼装时,应注意一下两点:一是调整好凸轮与腔外壁间隙;二是要查验卡紧螺铨有无形变。

8、泵组装后,先手动盘车,假如阻力较大,或开卡,应重装。