The cam-type double rotor pump is a high-tech and top-notch fluid delivery equipment imported and developed by LAFA from Sweden, and it is a multi-functional new rotor pump manufactured with advanced technology. The professional manufacturing technology and manufacturing precision of the products fully meet the international level.

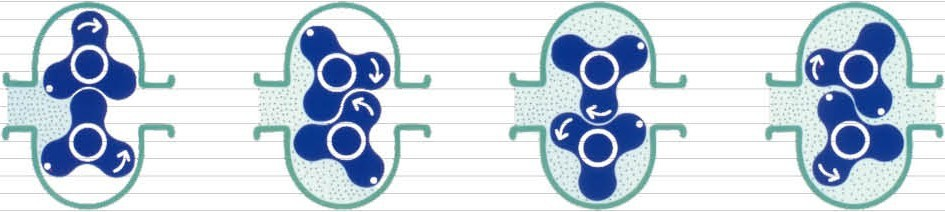

This product uses two synchronous rotors, the rotors are driven by a pair of synchronous gears in the box, and the rotors are driven by the main and auxiliary shafts to rotate synchronously in the opposite direction to make the pump The inner cavity of the pump is changed, thus forming a higher vacuum degree and discharge pressure, which is more suitable for the transportation of sanitary grades and corrosive high-viscosity media.

The manufacturing standards of this product are divided into five series: food grade, common type, special type, chemical type, and oil type. In terms of structure, it can be divided into two categories: high pressure and high viscosity, high pressure and low viscosity.

With the superior performance of the cam-type double-rotor pump, it can replace more commonly used centrifugal pumps, single-screw pumps, twin-screw pumps, etc.

Type | Capacity (L/r) | Flow (m3/h) | Power (kw) | Rotation speed (r/min) | Inlet&outlet (mm) |

15LF12-0.6A | 0.04 | 0.6 | 0.25-1.5 | 10-720 | 10 |

25LF12-2A | 0.15 | 2 | 0.25-2.2 | 10-721 | 25 |

40LF12-5A | 0.32 | 5 | 0.37-3.0 | 10-500 | 40 |

50LF12-10A | 0.65 | 10 | 1.5-7.5 | 10-500 | 50 |

60LF12-15A | 1.1 | 15 | 2.2-11 | 10-500 | 65 |

65LF12-20A | 1.74 | 20 | 2.2-15 | 10-500 | 65 |

75LF12-30A | 2.6 | 30 | 3.0-22 | 10-500 | 80 |

80LF12-40A | 3.65 | 40 | 4.0-30 | 10-500 | 80 |

100LF12-60A | 5.2 | 60 | 5.5-45 | 10-500 | 100 |

125LF12-80A | 6.8 | 80 | 7.5-55 | 10-500 | 125 |

140LF12-120A | 9.8 | 120 | 11-90 | 10-400 | 150 |

150LF12-150A | 12.8 | 150 | 15-160 | 10-400 | 150 |

200LF12-200A | 16 | 200 | 18.5-185 | 10-300 | 200 |

300LF12-300A | 24 | 300 | 22-185 | 10-270 | 300 |

在现实使用时,凸轮式双转子泵厂家选择转子泵的一个很重要的一个原因就是自吸,在基本参数明确的情形下,选用橡胶包覆材料转子能够促使转子泵具有极强的自吸能力。但一般在使用中,因为一些操作步骤和方案设计的原因,很有可能导致吸不上水,下面就带您了解下这一情况形成的原因。

1、管道

(1)转子泵在选用时充分考虑自吸能力时,一般会配套设施鹅颈法兰片。

(2)管道坡度,与转子泵进口的活套法兰的管道应斜放,往上会减少管道中大气的真空值,危害效率。

(3)管道连接发生空隙,气体直接进管道。

(4)垂直管道过长,转子泵自吸高度应调节在6-7米,低粘度物质尽量调整高度。

2、泵组

(1)配套设施电机额定功率低,传动比达不了额定转速。

(2)泵本身存在商品质量问题,硅油泵电机转子与泵壳间隙大,无法产生真空泵。

(3)电机转子长期运用毁坏。