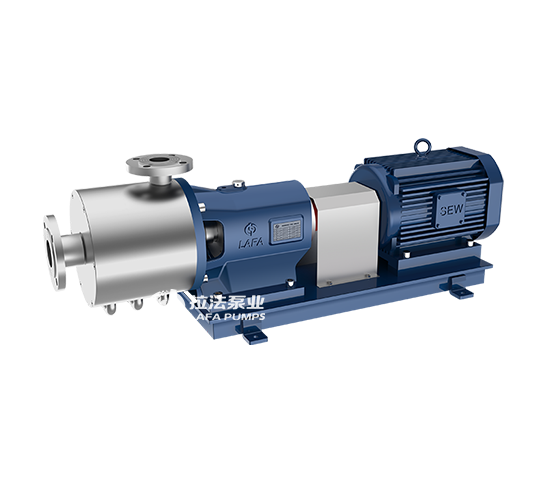

The homogeneous emulsification pump is a multi-mix emulsification equipment manufactured by LAFA Company using Swedish advanced technology. The professional manufacturing technology and processing precision of this product are ahead of similar products in the world.

The homogeneous emulsification pump is a high-efficiency product integrating mixing, decomposition, crushing, dissolving, refining, depolymerization, homogenization and emulsification. The main working parts are composed of rotor and stator. Under the action of the centrifugal force and hydraulic force of the rapid rotation of the rotor, the stator will strongly shear the material, centrifugal extrusion, impact crushing, liquid layer friction, turbulent flow and gas equalization, so that the immiscible solid phase, liquid phase, Various media such as gas are uniform and fine in an instant, dispersed and emulsified. After repeated cycles, the original product reaches a stable high-quality product.

After using this series of products, the original traditional production process is further simplified, the production efficiency is greatly improved, and the product quality is obviously improved.

| Homogeneous emulsification pump model technical parameter table | ||||||

| Type | Rotation speed (r/min) | Flow (m³/h) | Pressure (Mpa) | Power (Kw) | Lnlet (mm) | Outlet (mm) |

| LHB1_120F | 2950 | 3 | 0.1 | 3 | 50 | 40 |

| LHB1_140F | 2950 | 5 | 0.1 | 4 | 50 | 40 |

| LHB1_165F | 2950 | 10 | 0.15 | 5.5 | 65 | 50 |

| LHB1_185F | 2950 | 15 | 0.15 | 7.5 | 65 | 50 |

| LHB1_200F | 2950 | 20 | 0.15 | 15 | 80 | 65 |

| LHB1_220F | 2950 | 30 | 0.15 | 22 | 80 | 65 |

| LHB1_240F | 2950 | 50 | 0.2 | 22 | 100 | 80 |

| LHB1_260F | 2950 | 60 | 0.2 | 37 | 125 | 100 |

| LHB1_300F | 2950 | 80 | 0.25 | 45 | 125 | 100 |

| LHB3_120F | 2950 | 3 | 0.25 | 7.5 | 50 | 40 |

| LHB3_140F | 2950 | 5 | 0.25 | 11 | 50 | 40 |

| LHB3_165F | 2950 | 10 | 0.25 | 15 | 65 | 50 |

| LHB3_185F | 2950 | 15 | 0.25 | 30 | 65 | 50 |

| LHB3_200F | 2950 | 20 | 0.25 | 45 | 80 | 65 |

| LHB3_220F | 2950 | 30 | 0.25 | 55 | 80 | 65 |

| LHB3_240F | 2950 | 60 | 0.25 | 90 | 100 | 80 |

| LHB3_260F | 2950 | 100 | 0.25 | 132 | 125 | 100 |

| LHB3_300F | 1450 | 120 | 0.25 | 75 | 125 | 100 |

在运用地区上,由于工业生产技术实力发展的趋势,市场需求的升级,对于商品经济品质要求越来高,对于化工转子泵的要求也愈来愈高,因此功效多方位,方便使用、容易清理维修保养、乳化效果特别的好等特征的乳化机应用范围也越发广。对于只必须单一乳化的商品,HEB匀质乳化泵也是合理化挑选。

乳化泵是一种能够迅速且均匀地将一个或好几个相(液态,固体,气体)放入另一个不混溶的持续相(一般是液态)的机器。一般,相位差相互之间兼容问题。当输入外部动能时,二种原料重新排序成分布均匀的相。由于电机转子高转动的高断开速度和高频工业设备效用,HEC混和乳化均质泵在电机转子中间的窄小间隙中导致明显的工业设备和液压机裁剪,离心式挤压以及液层摩擦。产生混液(固体/液态),保湿乳液(液态/液态),塑料泡沫(气体/液态),比如由于撞击而发生的撕开和中合。