The cam-type double rotor pump is a high-tech and top-notch fluid delivery equipment imported and developed by LAFA from Sweden, and it is a multi-functional new rotor pump manufactured with advanced technology. The professional manufacturing technology and manufacturing precision of the products fully meet the international level.

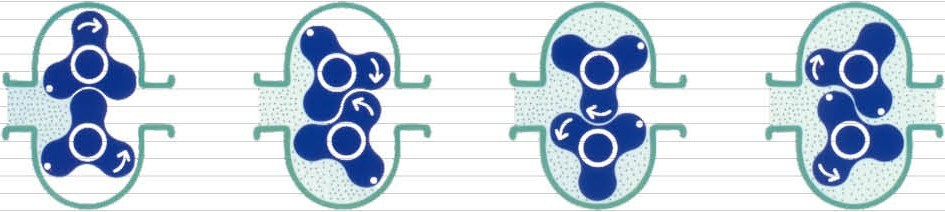

This product uses two synchronous rotors, the rotors are driven by a pair of synchronous gears in the box, and the rotors are driven by the main and auxiliary shafts to rotate synchronously in the opposite direction to make the pump The inner cavity of the pump is changed, thus forming a higher vacuum degree and discharge pressure, which is more suitable for the transportation of sanitary grades and corrosive high-viscosity media.

The manufacturing standards of this product are divided into five series: food grade, common type, special type, chemical type, and oil type. In terms of structure, it can be divided into two categories: high pressure and high viscosity, high pressure and low viscosity.

With the superior performance of the cam-type double-rotor pump, it can replace more commonly used centrifugal pumps, single-screw pumps, twin-screw pumps, etc.

Type | Capacity (L/r) | Flow (m3/h) | Power (kw) | Rotation speed (r/min) | Inlet&outlet (mm) |

15LF12-0.6A | 0.04 | 0.6 | 0.25-1.5 | 10-720 | 10 |

25LF12-2A | 0.15 | 2 | 0.25-2.2 | 10-721 | 25 |

40LF12-5A | 0.32 | 5 | 0.37-3.0 | 10-500 | 40 |

50LF12-10A | 0.65 | 10 | 1.5-7.5 | 10-500 | 50 |

60LF12-15A | 1.1 | 15 | 2.2-11 | 10-500 | 65 |

65LF12-20A | 1.74 | 20 | 2.2-15 | 10-500 | 65 |

75LF12-30A | 2.6 | 30 | 3.0-22 | 10-500 | 80 |

80LF12-40A | 3.65 | 40 | 4.0-30 | 10-500 | 80 |

100LF12-60A | 5.2 | 60 | 5.5-45 | 10-500 | 100 |

125LF12-80A | 6.8 | 80 | 7.5-55 | 10-500 | 125 |

140LF12-120A | 9.8 | 120 | 11-90 | 10-400 | 150 |

150LF12-150A | 12.8 | 150 | 15-160 | 10-400 | 150 |

200LF12-200A | 16 | 200 | 18.5-185 | 10-300 | 200 |

300LF12-300A | 24 | 300 | 22-185 | 10-270 | 300 |

有一些顾客根据准确测量,虽然蓄水池或冷却塔到水源水面的间隔还略低于宁波转子泵水泵扬程,但还是提出水量小或提不了水。其原因常是管道太长、自来水管拐弯多,水流在管道里的阻力损害太大。

一般情况下90度弯管比120度弯头摩擦阻力大,每一90度弯管水泵扬程损害约0.5-1米,每20米管道的摩擦阻力可使水泵扬程损害约1米。

膜过滤是指选用物理阻碍(似水渗透膜)从待净化水中分离颗粒杂质的过程。据了解,某省一家水处理厂应用14台国泰转子泵开展膜过滤,泵排量总计达10,000m³/h,这些泵提取等候根据膜开展净化水,水可以从膜上的小孔开展渗入,而固态和细菌等则不能通过膜,从而使水得到净化。

清理膜的工艺包含用过滤水定期对膜开展反冲洗。针对转子泵厂家的操作员而言,一台能够反向操作的泵尤为重要。这些泵也必须有很好的吸进作用。因为过滤操作时需要泵提取次数与反冲洗阶段不同,因而可使用变频器调节转子泵速度。