The cam-type double rotor pump is a high-tech and top-notch fluid delivery equipment imported and developed by LAFA from Sweden, and it is a multi-functional new rotor pump manufactured with advanced technology. The professional manufacturing technology and manufacturing precision of the products fully meet the international level.

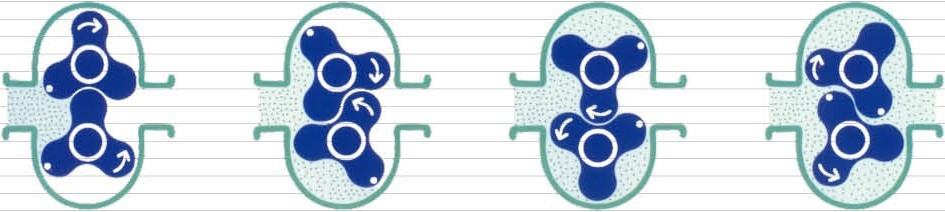

This product uses two synchronous rotors, the rotors are driven by a pair of synchronous gears in the box, and the rotors are driven by the main and auxiliary shafts to rotate synchronously in the opposite direction to make the pump The inner cavity of the pump is changed, thus forming a higher vacuum degree and discharge pressure, which is more suitable for the transportation of sanitary grades and corrosive high-viscosity media.

The manufacturing standards of this product are divided into five series: food grade, common type, special type, chemical type, and oil type. In terms of structure, it can be divided into two categories: high pressure and high viscosity, high pressure and low viscosity.

With the superior performance of the cam-type double-rotor pump, it can replace more commonly used centrifugal pumps, single-screw pumps, twin-screw pumps, etc.

Type | Capacity (L/r) | Flow (m3/h) | Power (kw) | Rotation speed (r/min) | Inlet&outlet (mm) |

15LF12-0.6A | 0.04 | 0.6 | 0.25-1.5 | 10-720 | 10 |

25LF12-2A | 0.15 | 2 | 0.25-2.2 | 10-721 | 25 |

40LF12-5A | 0.32 | 5 | 0.37-3.0 | 10-500 | 40 |

50LF12-10A | 0.65 | 10 | 1.5-7.5 | 10-500 | 50 |

60LF12-15A | 1.1 | 15 | 2.2-11 | 10-500 | 65 |

65LF12-20A | 1.74 | 20 | 2.2-15 | 10-500 | 65 |

75LF12-30A | 2.6 | 30 | 3.0-22 | 10-500 | 80 |

80LF12-40A | 3.65 | 40 | 4.0-30 | 10-500 | 80 |

100LF12-60A | 5.2 | 60 | 5.5-45 | 10-500 | 100 |

125LF12-80A | 6.8 | 80 | 7.5-55 | 10-500 | 125 |

140LF12-120A | 9.8 | 120 | 11-90 | 10-400 | 150 |

150LF12-150A | 12.8 | 150 | 15-160 | 10-400 | 150 |

200LF12-200A | 16 | 200 | 18.5-185 | 10-300 | 200 |

300LF12-300A | 24 | 300 | 22-185 | 10-270 | 300 |

乳化均质泵具备极高的稳定性和可靠的耐磨性。假如转子发生损坏,仅需更换转子密封口即可。泵的维护要求低,客户的内部人员可在较短时间内对泵实施维护,极大减少了关机和维护费用。

据了解,此项目为污水处理站更新改造工程,依据污水厂现况,保持原设计一级提升泵房、粗/细格栅、沉淀池不变,设计将原来氧化沟池体调整为分点进水倒置AAO工艺,划分部分原来二沉池容量作为生化池容量,剩余部分仍做为二沉池。新建深层控制部件,设计选用高效沉积+匀质滤料滤池过虑工艺做为此次更新改造工程深度工艺处理。废水经深度处理后,选用二氧化氯消毒,达标排放。水厂淤泥根据污泥池开展搜集,选用机械萃取、脱干后集中运输。

在生化池的污泥回流工艺中,因为运输物质淤泥固含量为3-6%,必须使化工转子泵能长久有效运作且拥有良好的根据特性,国泰转子泵选用全橡胶包覆的转子,具有很好的自吸能力,能够满足9米自吸规定,无需其他灌泵的辅助设备,针对污水厂生化池的污泥回流,具有很好的实用性和技术优势。