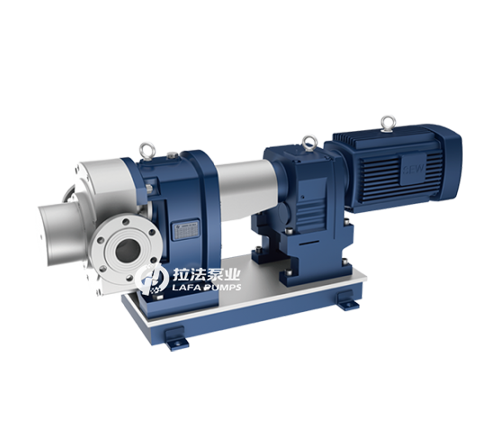

The chemical rotor pump is based on the customer's special working conditions, and the pump body and pump cover are equipped with insulation jackets. The pump body, pump cover, and rotor of special materials are hardened and double-sided The supporting structure and the heat preservation jacket can heat the pump body through steam, hot water or heat transfer fluid to prevent the material from solidifying on the pump body and the end faces of the dynamic and static rings, so that the pump will be stuck and the mechanical seal will be damaged during start-up operation, and the mechanical seal will be protected. protection of. It is suitable for working conditions where the viscosity of the material is greatly affected by temperature.

Type | Capacity (L/r) | Flow (m3/h) | Power (kw) | Rotation speed (r/min) | Inlet&outlet (mm) |

15LF12-0.6A | 0.04 | 0.6 | 0.25-1.5 | 10-720 | 10 |

25LF12-2A | 0.15 | 2 | 0.25-2.2 | 10-721 | 25 |

40LF12-5A | 0.32 | 5 | 0.37-3.0 | 10-500 | 40 |

50LF12-10A | 0.65 | 10 | 1.5-7.5 | 10-500 | 50 |

60LF12-15A | 1.1 | 15 | 2.2-11 | 10-500 | 65 |

65LF12-20A | 1.74 | 20 | 2.2-15 | 10-500 | 65 |

75LF12-30A | 2.6 | 30 | 3.0-22 | 10-500 | 80 |

80LF12-40A | 3.65 | 40 | 4.0-30 | 10-500 | 80 |

100LF12-60A | 5.2 | 60 | 5.5-45 | 10-500 | 100 |

125LF12-80A | 6.8 | 80 | 7.5-55 | 10-500 | 125 |

140LF12-120A | 9.8 | 120 | 11-90 | 10-400 | 150 |

150LF12-150A | 12.8 | 150 | 15-160 | 10-400 | 150 |

200LF12-200A | 16 | 200 | 18.5-185 | 10-300 | 200 |

300LF12-300A | 24 | 300 | 22-185 | 10-270 | 300 |

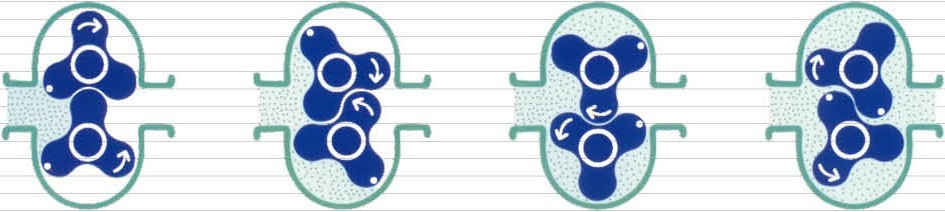

若使凸轮转子泵可靠工作上务必限制转速。危害转速的原因如下所示:

吸入性能。泵转速越快,其流量越多,转速不仅危害HEX1均质乳化泵吸入腔的损失,而且当转速提高到一定的水平时,就会产生吸入压力下物质来不进入或者赶不及弥漫着密闭性腔,使其发生某种真空泵状况。凸轮转子泵具有很好的吸入性能,一般在运输凉水时,泵在一定标准下吸上绝高可达8.5米。当运送高年底物质时,应将泵的进口货管布局成工作压力进口货为正压力,即泵出自于逆流的部位,使物质能成功进入密闭性腔。

凸轮式双转子泵是一种特别时髦的机械设备,在实际运行中,管道粘度泵无需拆卸泵体和管路就可以维修,且维持成本低,使用年限长。由于转子泵特有的原理,它在运输低粘度物料和挥发性物料方面拥有显着的优势。