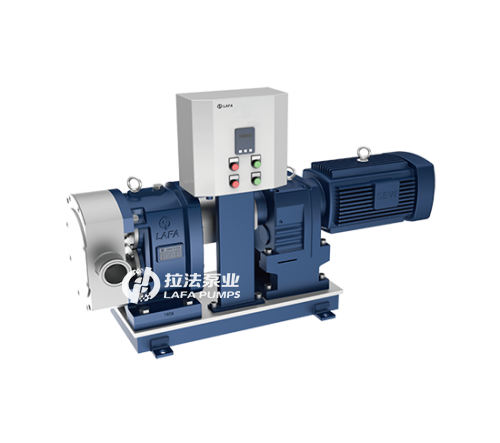

The cam-type double rotor pump is a high-tech and top-notch fluid delivery equipment imported and developed by LAFA from Sweden, and it is a multi-functional new rotor pump manufactured with advanced technology. The professional manufacturing technology and manufacturing precision of the products fully meet the international level.

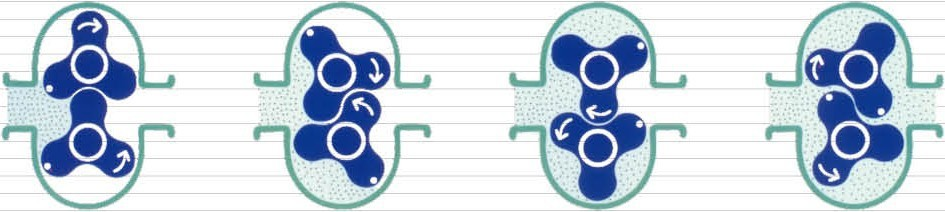

This product uses two synchronous rotors, the rotors are driven by a pair of synchronous gears in the box, and the rotors are driven by the main and auxiliary shafts to rotate synchronously in the opposite direction to make the pump The inner cavity of the pump is changed, thus forming a higher vacuum degree and discharge pressure, which is more suitable for the transportation of sanitary grades and corrosive high-viscosity media.

The manufacturing standards of this product are divided into five series: food grade, common type, special type, chemical type, and oil type. In terms of structure, it can be divided into two categories: high pressure and high viscosity, high pressure and low viscosity.

With the superior performance of the cam-type double-rotor pump, it can replace more commonly used centrifugal pumps, single-screw pumps, twin-screw pumps, etc.

Type | Capacity (L/r) | Flow (m3/h) | Power (kw) | Rotation speed (r/min) | Inlet&outlet (mm) |

15LF12-0.6A | 0.04 | 0.6 | 0.25-1.5 | 10-720 | 10 |

25LF12-2A | 0.15 | 2 | 0.25-2.2 | 10-721 | 25 |

40LF12-5A | 0.32 | 5 | 0.37-3.0 | 10-500 | 40 |

50LF12-10A | 0.65 | 10 | 1.5-7.5 | 10-500 | 50 |

60LF12-15A | 1.1 | 15 | 2.2-11 | 10-500 | 65 |

65LF12-20A | 1.74 | 20 | 2.2-15 | 10-500 | 65 |

75LF12-30A | 2.6 | 30 | 3.0-22 | 10-500 | 80 |

80LF12-40A | 3.65 | 40 | 4.0-30 | 10-500 | 80 |

100LF12-60A | 5.2 | 60 | 5.5-45 | 10-500 | 100 |

125LF12-80A | 6.8 | 80 | 7.5-55 | 10-500 | 125 |

140LF12-120A | 9.8 | 120 | 11-90 | 10-400 | 150 |

150LF12-150A | 12.8 | 150 | 15-160 | 10-400 | 150 |

200LF12-200A | 16 | 200 | 18.5-185 | 10-300 | 200 |

300LF12-300A | 24 | 300 | 22-185 | 10-270 | 300 |

从安装和维护化工转子泵全过程清除振动

1、安装前检查泵轴、电机轴承、驱动轴是否有弯曲变形、质量轴力的情况。

2、地脚螺丝间距是否优良,延展性柱销和弹性抛圈结合不能太紧,连轴器螺纹与轴的互相配合是不是太松,若过松,了采用比如喷涂的方法来减少连轴器外径直至其做到间隙配合所的需求规格,然后将连轴器固定不动在轴上。

3、间隙值是否符合要求,各个地方润滑是否优良,提升泵的轴抽瓦检修技术实力,严苛遵照先刮瓦、后研磨、在刮瓦的循环操作程序,确保活塞销与轴劲的碰触总面积做到要求的规范。

4、妥善处理HEB均质乳化泵有震动的支点件的疲倦情况,防止糖浆泵因为难度和弯曲应变降低造成共振频率减少。

5、确保电动机轴承间隙适合,定期维护,易损坏零件。