According to the material characteristics of the customer, during the operation of the rotor pump, the material flow rate is uneven or when the material is cut off, the rotor pump will be idling. The rotor pump with sealed structure, the mechanical seal of the rotor pump is equipped with an oil cup, the main function is to optimize the lubricity of the mechanical seal, so as to realize the idling of the mechanical seal in a short time, and prevent the dry grinding of the mechanical seal during operation .

Type | Capacity (L/r) | Flow (m3/h) | Power (kw) | Rotation speed (r/min) | Inlet&outlet (mm) |

15LF12-0.6A | 0.04 | 0.6 | 0.25-1.5 | 10-720 | 10 |

25LF12-2A | 0.15 | 2 | 0.25-2.2 | 10-721 | 25 |

40LF12-5A | 0.32 | 5 | 0.37-3.0 | 10-500 | 40 |

50LF12-10A | 0.65 | 10 | 1.5-7.5 | 10-500 | 50 |

60LF12-15A | 1.1 | 15 | 2.2-11 | 10-500 | 65 |

65LF12-20A | 1.74 | 20 | 2.2-15 | 10-500 | 65 |

75LF12-30A | 2.6 | 30 | 3.0-22 | 10-500 | 80 |

80LF12-40A | 3.65 | 40 | 4.0-30 | 10-500 | 80 |

100LF12-60A | 5.2 | 60 | 5.5-45 | 10-500 | 100 |

125LF12-80A | 6.8 | 80 | 7.5-55 | 10-500 | 125 |

140LF12-120A | 9.8 | 120 | 11-90 | 10-400 | 150 |

150LF12-150A | 12.8 | 150 | 15-160 | 10-400 | 150 |

200LF12-200A | 16 | 200 | 18.5-185 | 10-300 | 200 |

300LF12-300A | 24 | 300 | 22-185 | 10-270 | 300 |

目前,全球各国凸轮式双转子泵结构方式实际有立式和立式二种。立式构造相对性于立式构造的重心点较低,运行中稳定性更强,是现阶段广泛应用的构造,但是其占地总面积较立式构造的重心点较低,运行时稳定性更强,是现阶段广泛应用的构造,但是其占地总面积较立式构造要大一些。

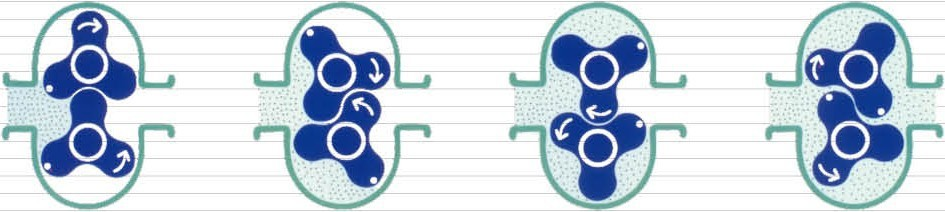

凸轮转子泵是一种动能转换的机器,能量的转化全过程必定随着能量的损失,而效率高就是这种变换的衡量,如何提升高剪切均质泵的高效率,减少能量的损失呢?就需要弄清楚凸轮转子泵内能量的损失。

在凸轮转子泵型号挑选全过程中,型号挑选项目工程师会常常碰到进出口管道长度、管道直径已经知道,而顾客本身不清楚务必很大的压力能够令人满意的情况,因而卫生型转子泵的应用管道损失十分必需。