The cam-type double rotor pump is a high-tech and top-notch fluid delivery equipment imported and developed by LAFA from Sweden, and it is a multi-functional new rotor pump manufactured with advanced technology. The professional manufacturing technology and manufacturing precision of the products fully meet the international level.

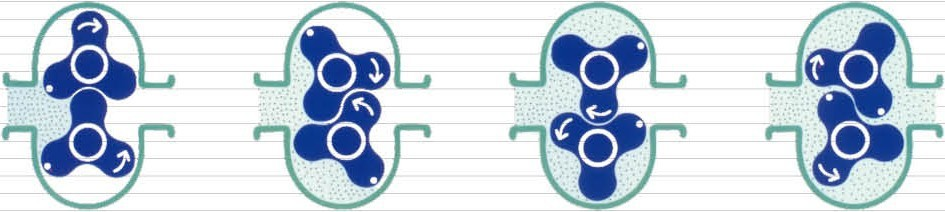

This product uses two synchronous rotors, the rotors are driven by a pair of synchronous gears in the box, and the rotors are driven by the main and auxiliary shafts to rotate synchronously in the opposite direction to make the pump The inner cavity of the pump is changed, thus forming a higher vacuum degree and discharge pressure, which is more suitable for the transportation of sanitary grades and corrosive high-viscosity media.

The manufacturing standards of this product are divided into five series: food grade, common type, special type, chemical type, and oil type. In terms of structure, it can be divided into two categories: high pressure and high viscosity, high pressure and low viscosity.

With the superior performance of the cam-type double-rotor pump, it can replace more commonly used centrifugal pumps, single-screw pumps, twin-screw pumps, etc.

Type | Capacity (L/r) | Flow (m3/h) | Power (kw) | Rotation speed (r/min) | Inlet&outlet (mm) |

15LF12-0.6A | 0.04 | 0.6 | 0.25-1.5 | 10-720 | 10 |

25LF12-2A | 0.15 | 2 | 0.25-2.2 | 10-721 | 25 |

40LF12-5A | 0.32 | 5 | 0.37-3.0 | 10-500 | 40 |

50LF12-10A | 0.65 | 10 | 1.5-7.5 | 10-500 | 50 |

60LF12-15A | 1.1 | 15 | 2.2-11 | 10-500 | 65 |

65LF12-20A | 1.74 | 20 | 2.2-15 | 10-500 | 65 |

75LF12-30A | 2.6 | 30 | 3.0-22 | 10-500 | 80 |

80LF12-40A | 3.65 | 40 | 4.0-30 | 10-500 | 80 |

100LF12-60A | 5.2 | 60 | 5.5-45 | 10-500 | 100 |

125LF12-80A | 6.8 | 80 | 7.5-55 | 10-500 | 125 |

140LF12-120A | 9.8 | 120 | 11-90 | 10-400 | 150 |

150LF12-150A | 12.8 | 150 | 15-160 | 10-400 | 150 |

200LF12-200A | 16 | 200 | 18.5-185 | 10-300 | 200 |

300LF12-300A | 24 | 300 | 22-185 | 10-270 | 300 |

1、机械耗损

通常是叶轮前、盖板、凸轮转子泵腔内液态、叶轮前、盖板表面、转子泵腔内的摩擦损失(又称园盘损失)。

凸轮式转子泵配件园盘耗损占了很大一部分,甚至占到了有效功率的30%。园盘耗损与叶轮转速的三次方正相关关联,与叶轮直径五次方正相关关联。因而,叶轮的直径越多,损失越多。尽管园盘损失与转子转速成正比关联,但随着扬程的增大,叶轮直径相应减小,园盘损失呈五次方降低,因而,转速越大,叶轮损失就越低,这便是转子泵发展的原因之一。

2、容量耗损

叶轮部分液态根据叶轮密封圈空隙泄露回叶轮进口,使叶轮不能有效利用,进而造成损失。因而,密封环空隙越小越好,但由于加工、安装等因素,空隙太小会导致偏磨或卡住。

3、水力耗损

流体的过流部分(从进口至出口)势必会产生速度与方位上的变化,即水力损失。专业凸轮式转子泵厂家为了减少这类损失,应尽量选良好的水力模型,以提升过流元件的光滑度。