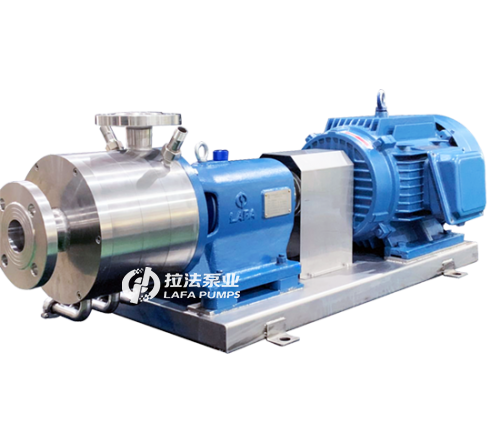

The homogeneous emulsification pump is a multi-mix emulsification equipment manufactured by LAFA Company using Swedish advanced technology. The professional manufacturing technology and processing precision of this product are ahead of similar products in the world.

The homogeneous emulsification pump is a high-efficiency product integrating mixing, decomposition, crushing, dissolving, refining, depolymerization, homogenization and emulsification. The main working parts are composed of rotor and stator. Under the action of the centrifugal force and hydraulic force of the rapid rotation of the rotor, the stator will strongly shear the material, centrifugal extrusion, impact crushing, liquid layer friction, turbulent flow and gas equalization, so that the immiscible solid phase, liquid phase, Various media such as gas are uniform and fine in an instant, dispersed and emulsified. After repeated cycles, the original product reaches a stable high-quality product.

After using this series of products, the original traditional production process is further simplified, the production efficiency is greatly improved, and the product quality is obviously improved.

| Homogeneous emulsification pump model technical parameter table | ||||||

| Type | Rotation speed (r/min) | Flow (m³/h) | Pressure (Mpa) | Power (Kw) | Lnlet (mm) | Outlet (mm) |

| LHB1_120F | 2950 | 3 | 0.1 | 3 | 50 | 40 |

| LHB1_140F | 2950 | 5 | 0.1 | 4 | 50 | 40 |

| LHB1_165F | 2950 | 10 | 0.15 | 5.5 | 65 | 50 |

| LHB1_185F | 2950 | 15 | 0.15 | 7.5 | 65 | 50 |

| LHB1_200F | 2950 | 20 | 0.15 | 15 | 80 | 65 |

| LHB1_220F | 2950 | 30 | 0.15 | 22 | 80 | 65 |

| LHB1_240F | 2950 | 50 | 0.2 | 22 | 100 | 80 |

| LHB1_260F | 2950 | 60 | 0.2 | 37 | 125 | 100 |

| LHB1_300F | 2950 | 80 | 0.25 | 45 | 125 | 100 |

| LHB3_120F | 2950 | 3 | 0.25 | 7.5 | 50 | 40 |

| LHB3_140F | 2950 | 5 | 0.25 | 11 | 50 | 40 |

| LHB3_165F | 2950 | 10 | 0.25 | 15 | 65 | 50 |

| LHB3_185F | 2950 | 15 | 0.25 | 30 | 65 | 50 |

| LHB3_200F | 2950 | 20 | 0.25 | 45 | 80 | 65 |

| LHB3_220F | 2950 | 30 | 0.25 | 55 | 80 | 65 |

| LHB3_240F | 2950 | 60 | 0.25 | 90 | 100 | 80 |

| LHB3_260F | 2950 | 100 | 0.25 | 132 | 125 | 100 |

| LHB3_300F | 1450 | 120 | 0.25 | 75 | 125 | 100 |

1、精细乳化泵的机械密封遇到凝固性物料,务必每个班下班了前,将工作中腔里的物料用溶液清理。

2、乳化泵的机械密封是一个零配件,其使用期限与工作状况标准和维护有关,本设备上的机械密封是依靠物料来排热的,因而禁止在机械密封的腔身体无物料的情形下运作,防止损坏机械密封。

常见问题:

1、乳化泵放置地要平稳,避免多少起伏而出现多余撞击。

2、高剪切乳化泵在使用时使用职工要对其开关电源进行检查,看一下电源插头是否适当连接。

3、实际操作职工要明白在没有液体进入均质乳化泵的泵腔中,如没有则立刻暂停该工作上,其防止损坏机械密封。

4、乳化泵应用时有些物料流通性比较差,比如粘度性比较强的,建议采用相对应高剪切匀质乳化泵机械设备进行运送。

5、倘若乳化泵体上转为与机械设备上的红色箭头的方位发生偏差,要检查物料是否进入腔身体内,等调节好乳化泵的转为后明确后重新启动电机。